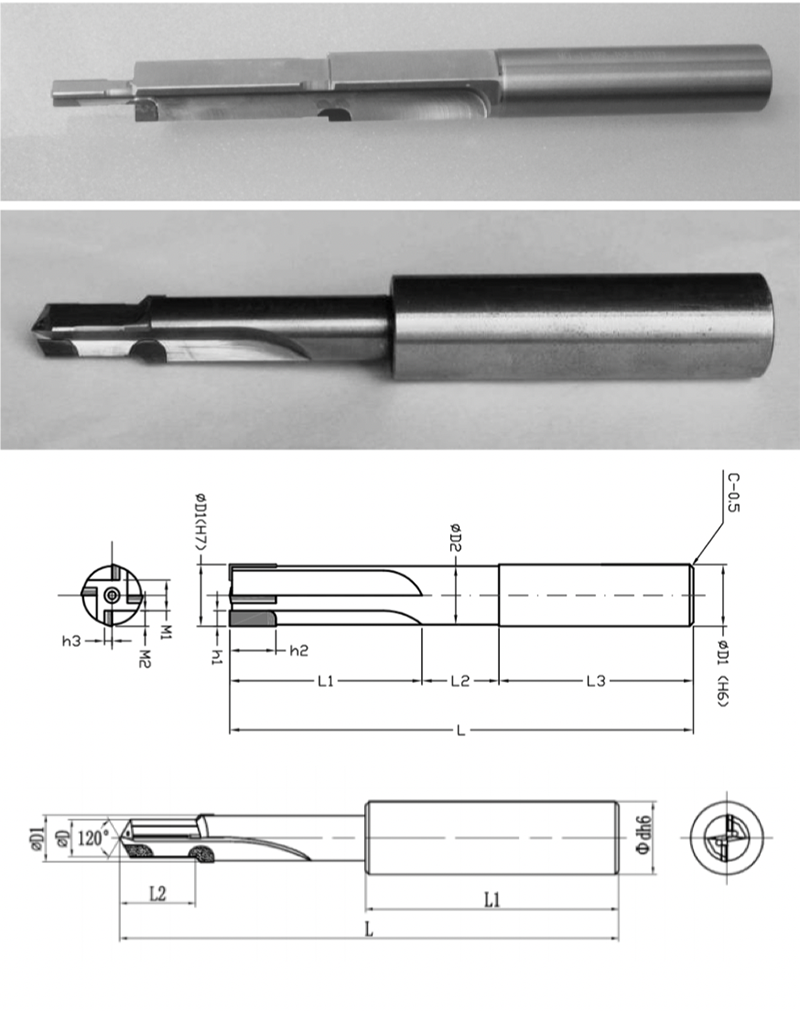

PCD Endmills | PCD Reamers

PCD Endmills have advantages over the average tungsten carbide milling tool, the PCD blanks feature high hardness, high abrasive resistance, high thermal conductivity and strong toughness.

PCD Endmills are used to process workpieces of various materials, including copper, aluminum, copper alloy, aluminum alloy and composite material. It also can be used to process cast aluminum alloy engine case.

PCD Endmills can be customized, some common sizes are as follows:

(CBN Endmills, PCD Reamers, PCD Drills, CBN Drills are also available)

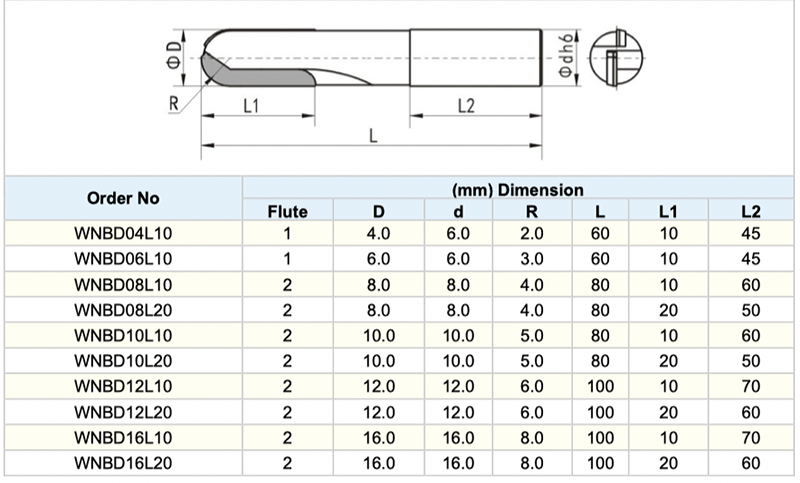

1. PCD Ball Nose Endmills (1 or 2 PCD flutes are available)

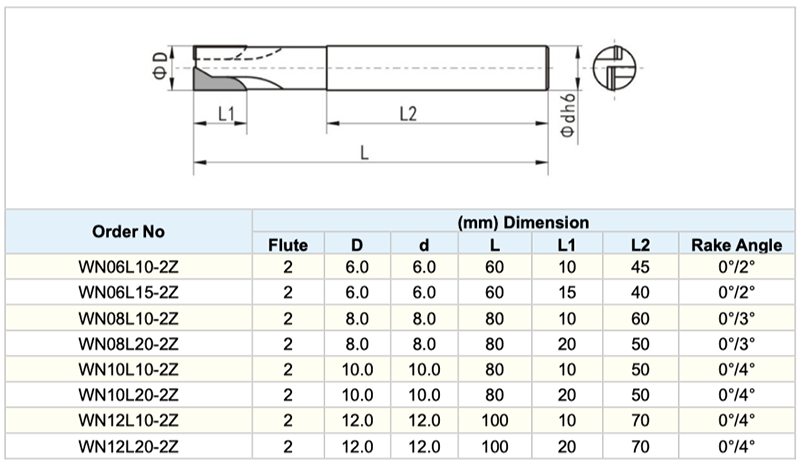

2. PCD Endmills with 2 PCD flutes

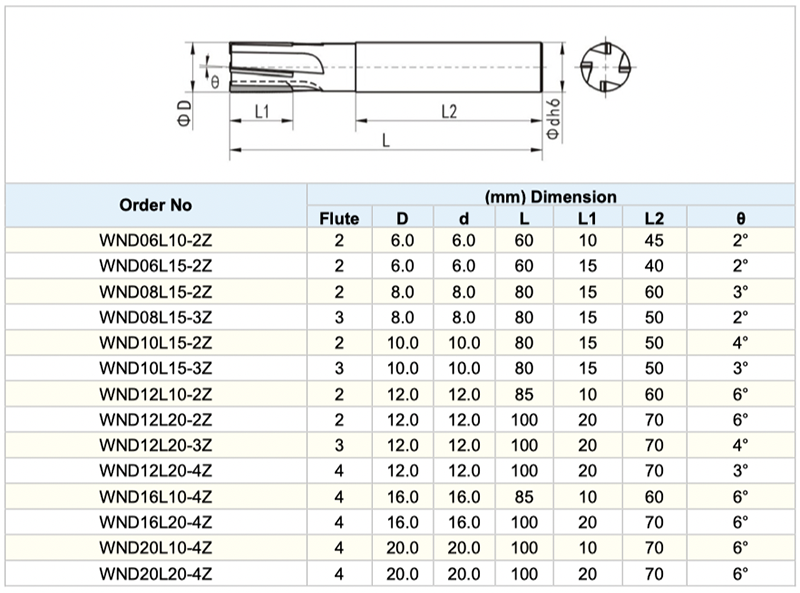

3. Helical PCD Endmills (2, 3, 4 PCD flutes are available)

Advantages of PCD Endmills

1. The PCD Endmills feature high processing precision and high processing efficiency;

2. The PCD Endmills can realize high speed cutting and hard material cutting;

3. With the features of high abrasive resistance and thermal conductivity, PCD Endmills have a long service life that is 10 to 20 times tungsten carbide milling tools.

4. PCD Reamers - can be customized as customers' design and request