Tipped PCD Inserts | CVD Inserts

About PCD Inserts:

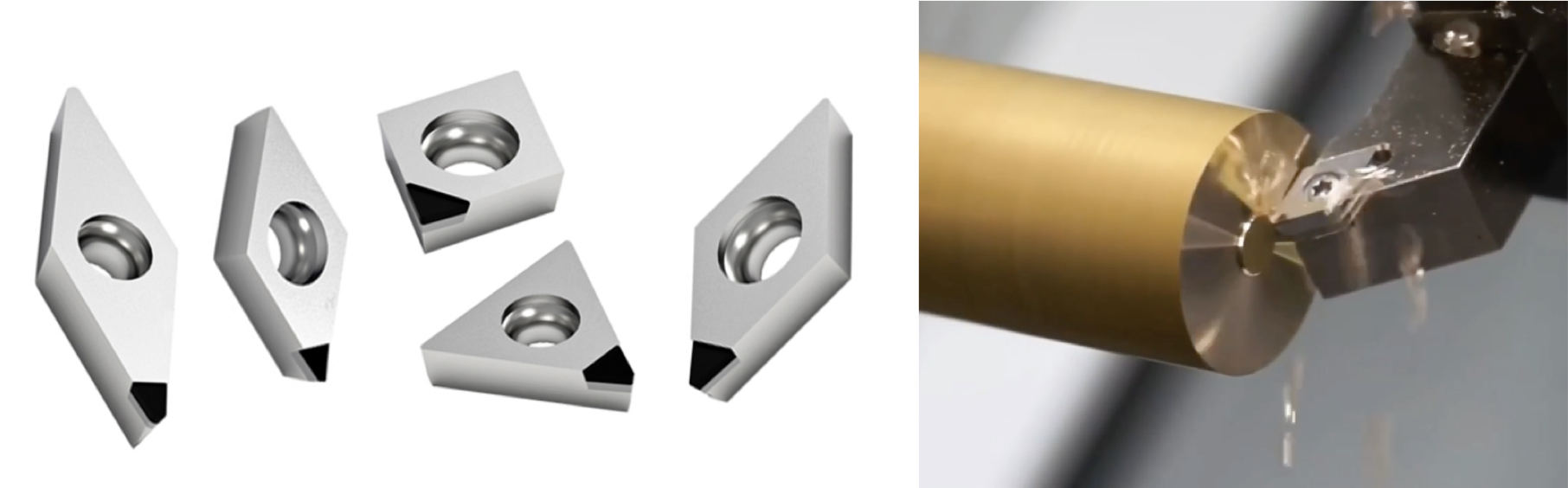

PCD (Polycrystalline Diamond) is micro sized diamond particles which are sintered together under super high temperature and pressure. The PCD blanks are made of PCD particles bonded on top of the layer of tungsten carbide. PCD inserts are made by PCD blanks brazed on carbide tungsten substrate.

About CVD Diamond Inserts:

CVD (chemical vapor deposition) inserts have the advantages of high hardness, strong wear resistance and strong stability. Compared to PCD inserts, CVD inserts have several times of PCD inserts, and have very excellent finishing and low friction coefficient which could reduce the friction heat and cutting force.

CVD inserts have very good working effect of finishing the materials aluminum, copper, tungsten alloy and other non-metal parts in auto parts and other industries.

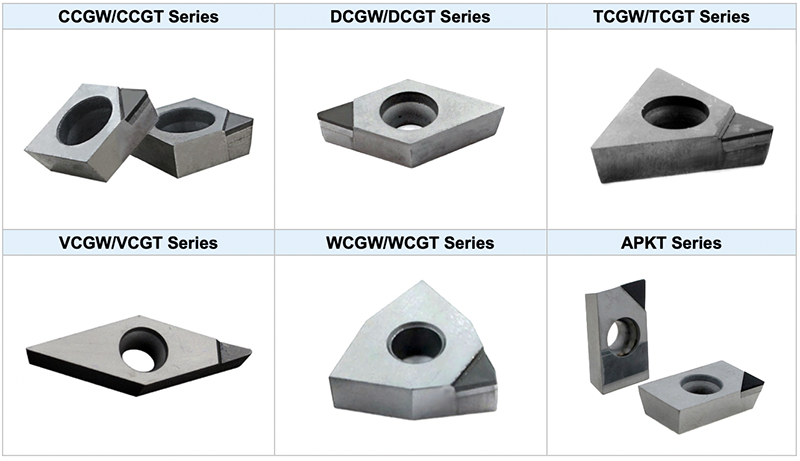

Various types of Tipped PCD Inserts and CVD Inserts:

Hot types: CCGW CCGT DCGW DCGT TCGW TCGT SCGW SCGT TCGT TCGW WCGW WCGT

This page does not show all the sizes of tipped PCD inserts, if you do not find the size you need, such as SCGW09T308, welcome you to contact us for detailed catalogs via email sales@weinotools.com.

Features of PCD Inserts:

1. PCD inserts have good processing effects with high abrasive resistance, high processing precision, good thermal conductivity and longer use life.

2. PCD inserts can reach high speed machining with improved resistance to wear.

4. PCD Inserts can improve the surface finishing.

5. PCD inserts can be used repeatedly, the PCD tips can be re-tipped and re-grinding, which help to lower your processing cost.

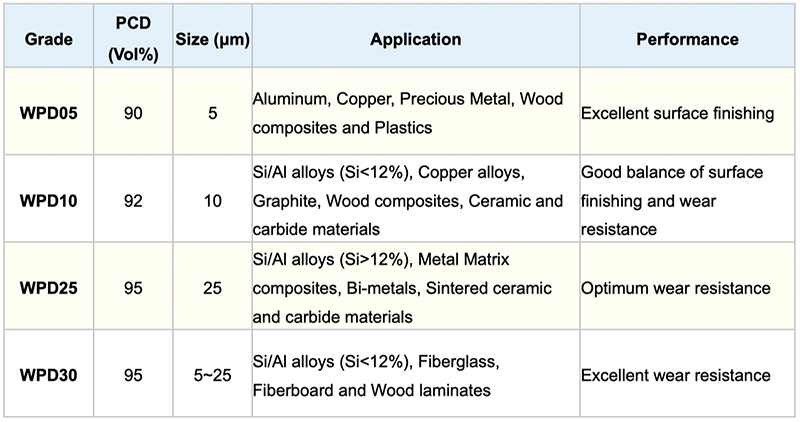

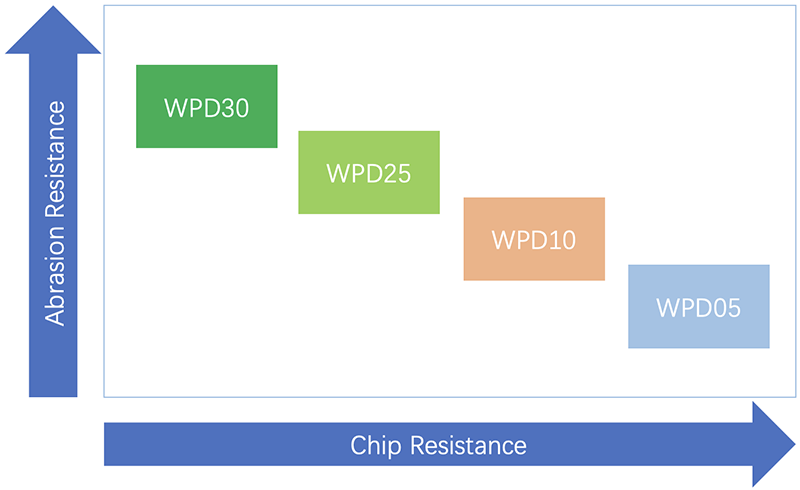

Grades of PCD Materials:

Application of PCD Inserts:

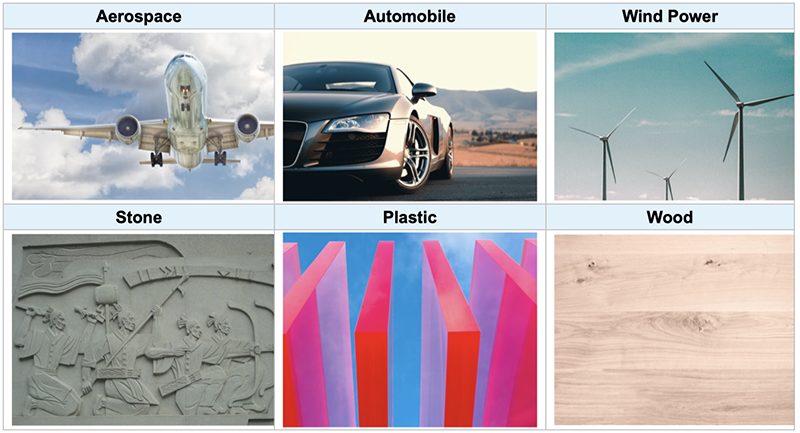

PCD Inserts can be used in lots of different processing operations, such as turning, milling, grooving, facing, drilling and boring. PCD Inserts are widely used in many industry fields, such as aerospace, automotive parts, wind power generation, and the wood and stone industry. Not only for aluminum, aluminum alloys, copper and copper alloys products, they also can be used to process non-ferrous metal and non-metal, such tungsten carbide, ceramic, carbon, plastic, stone and composite materials.

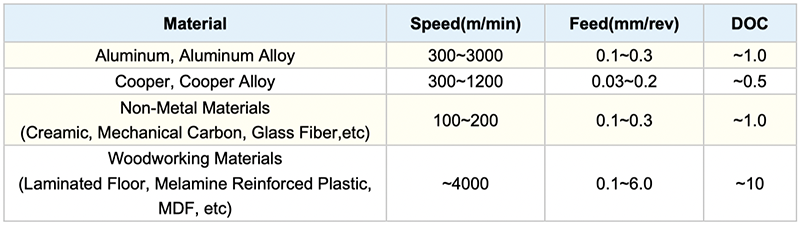

Recommended Cutting Parameters of PCD Inserts